- 您现在的位置:买卖IC网 > Sheet目录218 > CWR06NC105MR (Vishay Sprague)CAP TANT 1UF 50V 20% 2010

�� �

�

�

�Typical� Performance� Characteristics�

�www.vishay.com�

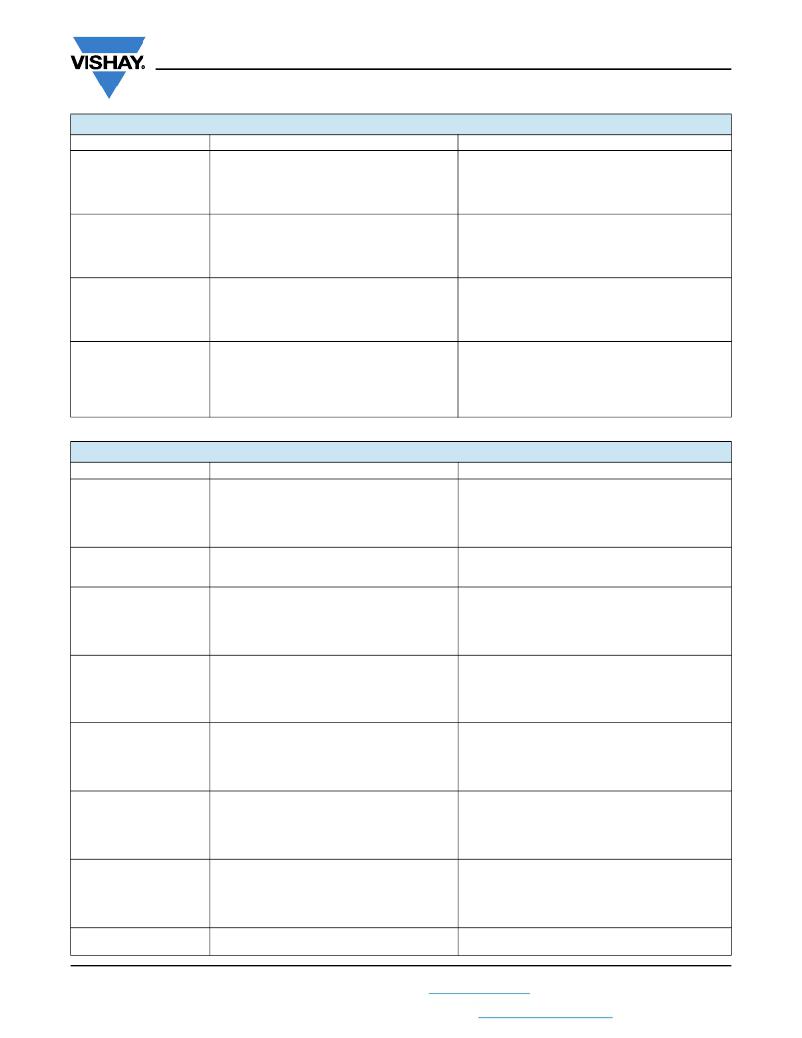

�CAPACITOR� ENVIRONMENTAL� CHARACTERISTICS�

�Vishay� Sprague�

�ITEM�

�CONDITION�

�ENVIRONMENTAL� CHARACTERISTICS�

�Humidity� tests�

�At� 40� °C/90� %� RH� 1000� h,� no� voltage� applied.� ?�

�Capacitance� change� ?�

�Cap.� ?� 600� μF� ?�

�Cap.� >� 600� μF� ?�

�Dissipation� factor�

�?�

�Within� ±� 10� %� of� initial� value� ?�

�Within� ±� 20� %� of� initial� value� ?�

�Not� to� exceed� 150� %� of� initial� ?�

�+25� °C� requirement�

�Temperature� cycles�

�Moisture� resistance�

�Thermal� shock�

�At� -55� °C/+125� °C,� 30� min� each,� for� 5� cycles.�

�MIL-STD-202,� method� 106� at� rated� voltage,�

�42� cycles.�

�Capacitors� are� subjected� to� 5� cycles� of� the�

�following:� ?�

�-55� °C� (+0� °C,� -5� °C)� for� 30� min,� then� ?�

�+25� °C� (+10� °C,� -5� °C)� for� 5� min,� then� ?�

�+125� °C� (+3� °C,� -0� °C)� for� 30� min,� then� ?�

�Capacitance� change� ?�

�Cap.� ?� 600� μF� ?�

�Cap.� >� 600� μF� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Capacitance� change� ?�

�Cap.� ?� 600� μF� ?�

�Cap.� >� 600� μF� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Capacitance� change� ?�

�Cap.� ?� 600� μF� ?�

�Cap.� >� 600� μF� ?�

�Dissipation� factor� ?�

�Leakage� current�

�?�

�Within� ±� 10� %� of� initial� value� ?�

�Within� ±� 20� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�?�

�Within� ±� 10� %� of� initial� value� ?�

�Within� ±� 20� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�?�

�Within� ±� 10� %� of� initial� value� ?�

�Within� ±� 20� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�+25� °C� (+10� °C,� -5� °C)� for� 5� min�

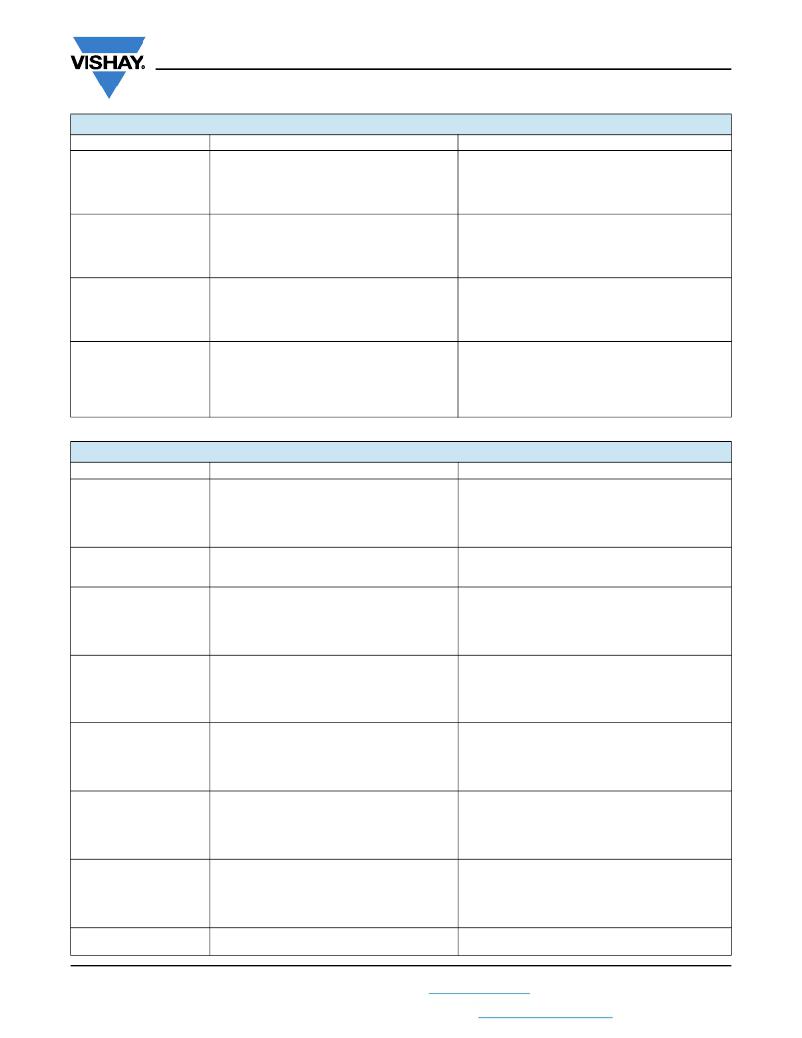

�MECHANICAL� PERFORMANCE� CHARACTERISTICS�

�TEST� CONDITION�

�CONDITION�

�POST� TEST� PERFORMANCE�

�Shear� test�

�Apply� a� pressure� load� of� 5� N� for� 10� s� ±� 1� s�

�horizontally� to� the� center� of� capacitor� side� body.�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Substrate� bend�

�Vibration�

�With� parts� soldered� onto� substrate� test� board,�

�apply� force� to� the� test� board� for� a� deflection�

�of� 3� mm,� for� a� total� of� 3� bends� at� a� rate� of� 1� mm/s.�

�MIL-STD-202,� method� 204,� condition� D,� 10� Hz� to�

�2000� Hz,� 20� g� peak�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Shock�

�MIL-STD-202,� method� 213B� shock� (specified�

�pulse),� condition� I,� 100� g� peak�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Resistance� to� solder� heat�

�?� Recommended� reflow� profiles� temperatures�

�and� durations� are� located� within� the� Capacitor�

�Series� Guides�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�?� Pb-free� and� lead-bearing� series� caps� are�

�backward� and� forward� compatible�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Solderability�

�MIL-STD-2002,� method� 208,� ANSI/J-STD-002,�

�test� B.� Applies� only� to� solder� and� tin� plated�

�terminations.� ?�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�Does� not� apply� to� gold� terminations.�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Resistance� to� solvents�

�MIL-STD-202,� method� 215�

�Capacitance� change� ?�

�Dissipation� factor� ?�

�Leakage� current�

�Within� ±� 10� %� of� initial� value� ?�

�Initial� specified� value� or� less� ?�

�Initial� specified� value� or� less�

�There� shall� be� no� mechanical� or� visual� damage� to�

�capacitors� post-conditioning.�

�Flammability�

�Encapsulent� materials� meet� UL� 94� V-0� with� an�

�oxygen� index� of� 32� %.�

�Revision:� 03-Feb-14�

�3�

�Document� Number:� 40088�

�For� technical� questions,� contact:� tantalum@vishay.com�

�THIS� DOCUMENT� IS� SUBJECT� TO� CHANGE� WITHOUT� NOTICE.� THE� PRODUCTS� DESCRIBED� HEREIN� AND� THIS� DOCUMENT�

�ARE� SUBJECT� TO� SPECIFIC� DISCLAIMERS,� SET� FORTH� AT� www.vishay.com/doc?91000�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

CWR15FK225KCLC

CAP TANT 2.2UF 10% 10V 0603

CWR29KC336KCXC

CAP TANT 33UF 25V 10% 2721

CWSB21AA2H

SWITCH ROCKER DPST 6A 250V

CWSB21DADF

SWITCH ROCKER DPST 9A 125V

CWSC21JDADS

SWITCH ROCKER DPST 9A 125V

CX2016DB27000D0GEJZ1

CRYSTAL 27.000MHZ 8PF SMD

CX2016DB40000D0FLJZ1

CRYSTAL 40.000MHZ 8PF SMD

CX2520DB20000D0FLJZ1

CRYSTAL 20.000MHZ 8PF SMD

相关代理商/技术参数

CWR06NC105MR/TR

制造商:Vishay Intertechnologies 功能描述:Cap Tant Solid 1uF 50V E CASE 20% (5.08 X 2.54 X 1.27mm) SMD (0.01%FR) 6 Ohm 125C T/R 制造商:Vishay Sprague 功能描述:CAP 1UF 50VDC 20% 5.08 X 2.54 X 1.27MM SMD 0.01% - Tape and Reel

CWR06NC105MRA

制造商:Vishay Sprague 功能描述:CAP 1UF 50VDC 20% 5.08 X 2.54 X 1.27MM SMD 0.01% - Bulk

CWR06NC105MRB

制造商:Vishay Sprague 功能描述:CAP 1UF 50VDC 20% 5.08 X 2.54 X 1.27MM SMD 0.01% - Bulk

CWR06NC105MRC

制造商:Vishay Sprague 功能描述:CAP 1UF 50VDC 20% 5.08 X 2.54 X 1.27MM SMD 0.01% - Bulk

CWR06NC154MC

制造商:Vishay Sprague 功能描述:CAP 0.15UF 50VDC 20% 2.54 X 1.27 X 1.27MM SMD 0.01% - Bulk

CWR06NC154MM

制造商:Vishay Sprague 功能描述:CAP 0.15UF 50VDC 20% 2.54 X 1.27 X 1.27MM SMD 1% - Bulk

CWR06NC154MP

制造商:Vishay Sprague 功能描述:CAP 0.15UF 50VDC 20% 2.54 X 1.27 X 1.27MM SMD 0.1% - Bulk

CWR06NC155JB/TR

制造商:Vishay Sprague 功能描述:CAP 1.5UF 50VDC 5% 5.59 X 3.43 X 1.78MM SMD 0.1% - Tape and Reel